I-SMAC inikeza amasethi aphelele emishini yemigqa yokupenda ngokufutha, imigqa yokumboza ngempuphu, imigqa ye-electrophoresis, imigqa ye-anodizing, ukwelashwa kwangaphambi kwesikhathi, ukuhlanza, ukomisa nokwelapha, ukudlulisa, kanye nokwelashwa kwegesi engcolile kanye namanzi angcolile. Imikhiqizo ye-SMAC isetshenziswa kabanzi ezimbonini ezifana nezimoto, izithuthuthu, izingxenye zamabhayisikili, imikhiqizo ye-IT, imikhiqizo ye-3C, izinto zasekhaya, ifenisha, izitsha zokupheka, izinto zokwakha zokuhlobisa, kanye nemishini yokwakha.

Ngemva kokuba umsebenzi uphume kuhhavini ophekayo, ungena ohlelweni lokupholisa ngokushesha ukuze kuphole.

Ukugqoka nge-electrophoretic kuhilela ukusebenzisa insimu kagesi yangaphandle ukusabalalisa izinhlayiya zopende ezifakwe i-ion ezilengiswe emanzini, okuzivumela ukuthi zimboze ubuso bento yokusebenza futhi zakhe ungqimba oluvikelayo. Le nqubo inezinzuzo eziningana:

Ukugqoka Okufanayo: Ukugqoka kusetshenziswa ngokulinganayo phezu kwendawo yonke.

Ukunamathela Okuqinile: Upende unamathela kahle ku-workpiece.

Ukulahleka Okuncane Kopende: Akukho ukuchithwa okuncane kwezinto zokumboza, okuholela emazingeni aphezulu okusetshenziswa.

Izindleko Zokukhiqiza Eziphansi: Izindleko zokukhiqiza zizonke ziyancipha.

Ukuncibilikisa Okusekelwe Emanzini: Upende ungancibilikiswa ngamanzi, kususwe izingozi zomlilo futhi kuthuthukiswe ukuphepha ngesikhathi sokukhiqiza.

Lezi zici zenza ukugqoka nge-electrophoretic kube ukukhetha okuthandwayo ezimbonini ezahlukahlukene.

Idivayisi ye-ultrafiltration (UF) ikakhulukazi iqukethe amamojula e-membrane, amaphampu, amapayipi, kanye nezinsimbi, konke kuhlanganiswe ndawonye. Ukuqinisekisa ukusebenza okuvamile kweyunithi ye-ultrafiltration, ngokuvamile ifakwe izinhlelo zokuhlunga nezokuhlanza. Inhloso eyinhloko ukwandisa impilo yesevisi yesisombululo sopende, ukuthuthukisa ikhwalithi yengubo, nokuqinisekisa inani elidingekayo le-ultrafiltrate lokusebenza okuvamile kwemishini.

Uhlelo lokuhlunga ngobuningi lwenzelwe uhlelo lokujikeleza oluqondile: upende we-electrophoretic ulethwa ngephampu yokuhambisa iye kusihlungi sangaphambi kohlelo lokuhlunga ngobuningi ukuze uthole ama-μs angu-25 okwelashwa kwangaphambi kokwelashwa. Ngemva kwalokhu, upende ungena eyunithi eyinhloko yohlelo lokuhlunga ngobuningi, lapho ukuhlukaniswa koketshezi kwenzeka khona nge-membrane module. Upende ohlanganisiwe ohlukaniswe uhlelo lokuhlunga ngobuningi ubuyiselwa ethangini le-electrophoretic ngokusebenzisa amapayipi okupenda ahlanganisiwe, kuyilapho i-ultrafiltrate igcinwa ethangini lokugcina ngobuningi. I-ultrafiltrate ethangini lokugcina ibe isidluliselwa endaweni yokusetshenziswa ngephampu yokudlulisa.

Isikhwama Sokushisa - Ukubhaka Nokuphola

Isikhwama sokushisa sisetshenziswa enqubweni yokubhaka nokulungisa izimbozo, ikakhulukazi ezimbonini ezifana nezimoto kanye nokukhiqiza. Nasi isifinyezo:

1. Umsebenzi: Isikhwama sokushisa sinikeza ukushisa okulawulwayo ezintweni zokusebenza ezimboziwe, okwenza kube lula ukunamathela kopende noma ezinye izinto ezimboziwe. Lokhu kuqinisekisa ukuthi ingubo inamathela kahle futhi ifinyelela ubulukhuni nokuqina okufiselekayo.

2. Umklamo: Izikhwama zokushisa zivame ukwenziwa ngezinto ezingashisi futhi zenzelwe ukusabalalisa ukushisa ngokulinganayo ebusweni bezinto zokusebenza.

3. Ukulawula Izinga Lokushisa: Ngokuvamile kuza nezinhlelo zokulawula izinga lokushisa ezakhelwe ngaphakathi ukuze kugcinwe amazinga okushisa adingekayo okupholisa, kuqinisekiswe imiphumela ehambisanayo.

4. Ukusebenza Kahle: Ukusebenzisa isikhwama sokushisa kunganciphisa ukusetshenziswa kwamandla uma kuqhathaniswa nama-oven avamile, njengoba kungagxila ukushisa ngqo ezingxenyeni ezilungiswayo.

5. Izicelo: Ivame ukusetshenziswa ezinqubweni zokumboza ngempuphu, ukupenda nge-electrophoretic, kanye nezinye izinhlelo zokusebenza lapho kudingeka khona ukuqeda okuhlala isikhathi eside.

Le ndlela ithuthukisa ikhwalithi yomkhiqizo oqediwe ngenkathi iqinisekisa ukusetshenziswa kahle kwezinsizakusebenza.

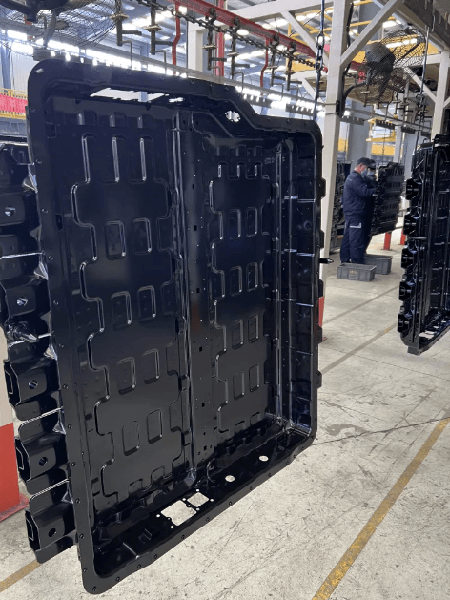

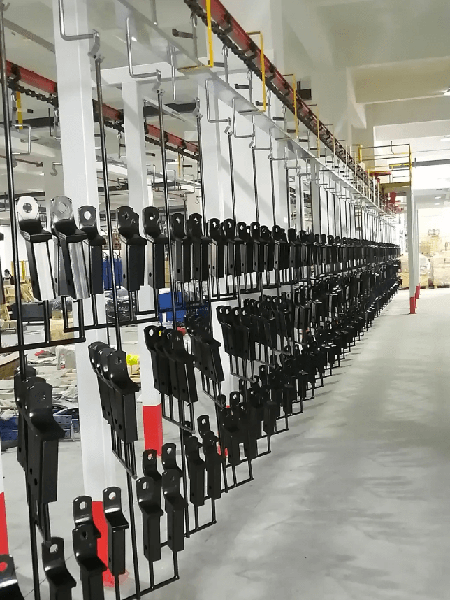

Uhlelo Lokudlulisa

Uhlelo lokuhambisa oluphezulu luqukethe izingxenye eziningana ezibalulekile, okuhlanganisa indlela yokushayela, idivayisi yokucindezela enezisindo, amaketanga, imizila eqondile, imizila egobile, imizila ye-telescopic, imizila yokuhlola, izinhlelo zokugcoba, izisekelo, iziphanyeko ezithwala umthwalo, izinhlelo zokulawula kagesi, kanye namadivayisi okuvikela ukunqwabelana ngokweqile. Imisebenzi yalo eyinhloko yilena elandelayo:

1. Ukusebenza: Uma injini ijikeleza, ishayela amathrekhi nge-reducer, enika amandla lonke uchungechunge lokuhambisa oluphezulu. Izinto zokusebenza zilengiswe ku-conveyor kusetshenziswa izinhlobo ezahlukene zama-hangers, okwenza kube lula ukuphatha nokusebenza.

2. Ukwenza ngokwezifiso: Ukuhlelwa komugqa wokuhambisa kunqunywa yindawo ethile yokusebenza kanye nokugeleza kwenqubo yomkhiqizo, okuhlangabezana ngempumelelo nezidingo zokukhiqiza.

3. Ukusebenza Kweketanga: Iketanga lisebenza njengengxenye yokudonsa ye-conveyor. Kufakwe uhlelo lokuthambisa oluzenzakalelayo eketangani ukuqinisekisa ukuthi wonke amalunga ahambayo athola inani eliqondile leketanga.

4. Ama-hangers: Ama-hangers asekela uchungechunge futhi athwala umthwalo wezinto ezithuthwayo emigwaqweni. Ukwakheka kwawo kunqunywa ukuma kwezingxenye zokusebenza kanye nezidingo ezithile zenqubo. Ama-hook kuma-hangers aphathwa ngokushisa okufanele ukuqinisekisa ukuthi amelana nokusetshenziswa isikhathi eside ngaphandle kokuqhekeka noma ukuwohloka.

Lolu hlelo lokudlulisa luthuthukisa ukusebenza kahle kanye nokuthembeka kwezicelo ezahlukahlukene zezimboni.

Isikhathi sokuthunyelwe: Julayi-25-2025