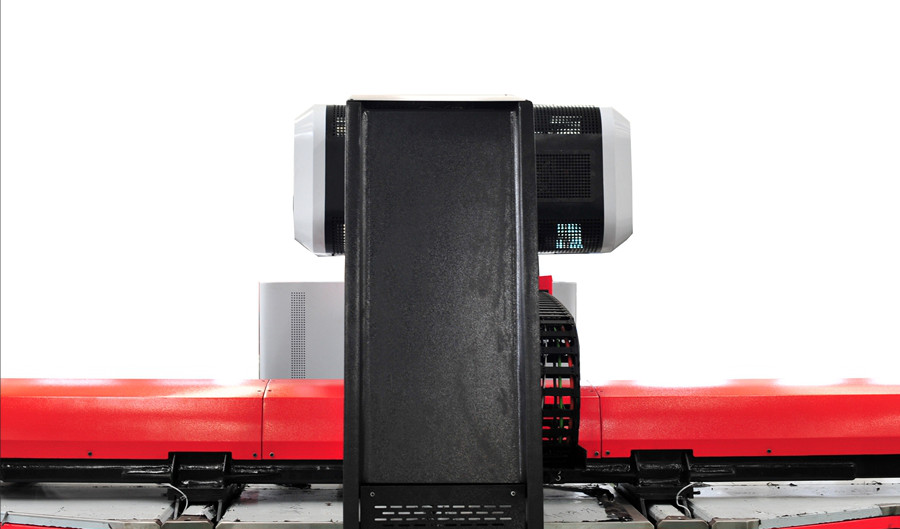

Ikhwalithi ephezulu CNC Turret Punch Machine

1. Uhlelo olulodwa lwe-servo motor driven, lusebenzisa i-servo motor neyunithi yokushayela eqhutshwa ngetorque enkulu enamandla okugcwala kakhulu ukuze kutholakale ukusetshenziswa kwamandla okuphansi, ukusebenza kahle kokudlulisela phambili, ukusebenza okuthembekile kanye nokugcinwa okulula.

(1) Isivinini esilungisekayo kanye nokushaywa unhlangothi

a. I-punch stroke ingakhethwa ngokusho kobukhulu beshidi ngokuzenzakalelayo, ukuthuthukisa ukusebenza kahle komsebenzi.

b. Ijubane le-punch liyalungiseka phakathi nendawo ngayinye yesiteshi ngasinye,

c. umshini ungabona isivinini esisheshayo ngesikhathi sokugijima okungenalutho kanye nesivinini esiphansi ngesikhathi se-punch yangempela, ngale ndlela, ikhwalithi ye-punch ingathuthukiswa ngokuphumelelayo, futhi akukho msindo ngempela ngesikhathi se-punch.

(2). Isistimu inezici ezinokuvikela okungaphezu kwamanje kanye namadivayisi okuvikela ukulayisha ngokweqile.

(3). I-punch force ingalungiswa ngokuzenzakalelayo ngokuya ngobukhulu beshidi kanye nesivinini sokugijima kwenqama ukwenza ikhwalithi yokushaya ifinyelele ezingeni eliphezulu.

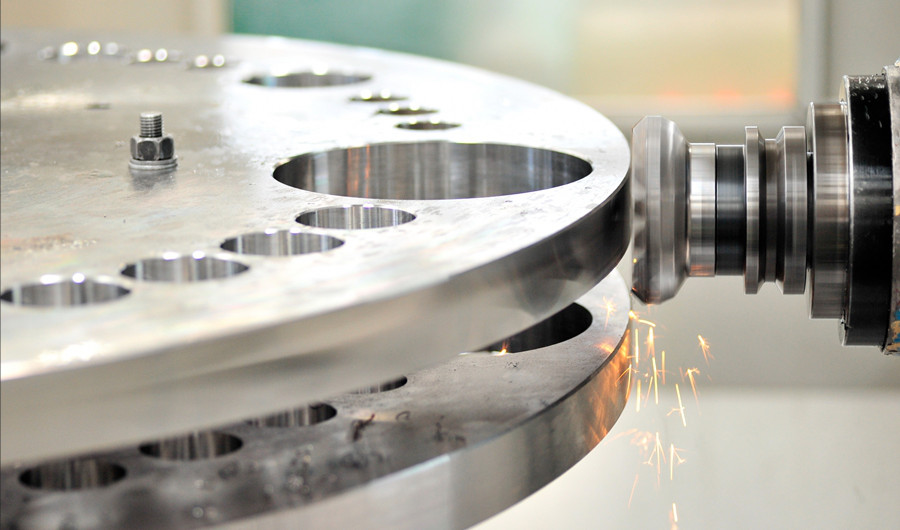

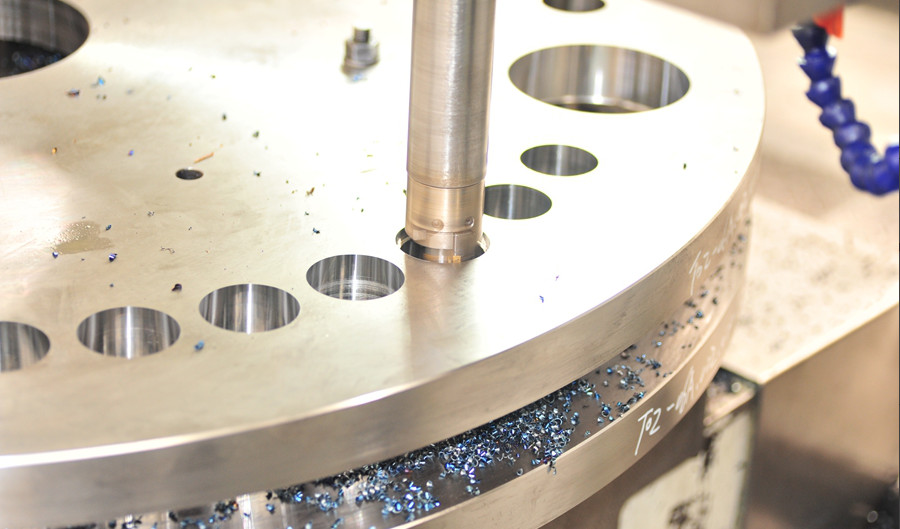

2. I-turret ene-bushing inqubo ngamabili

I-turret icutshungulwa idivayisi ekhethekile ukuze kuqinisekiswe i-coaxiality ye-turret engaphezulu nephansi futhi yandise impilo yesevisi ye-tooling; i-turret yasehlathini yenza lula ukwakheka kwe-turret ukunweba impilo yesevisi; ukusebenzisa isikhathi eside kungasetshenziswa ukukhulisa ukunemba komhlahlandlela nokwandisa impilo yesevisi yamathuluzi (yeshidi eliwugqinsi).

3. Izingxenye ze-pneumatic, zokugcoba kanye nezikagesi ezingenisiwe ziqinisekisa ukwethembeka kwawo wonke umshini.

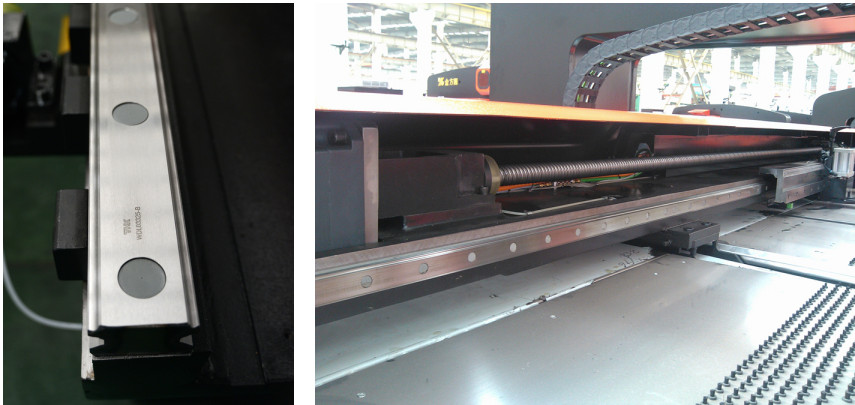

4. Umzila omkhulu oholayo kanye ne-ballscrew evela e-Japan noma eJalimane iqinisekisa ukuphakelwa okuphezulu okunembayo.

5. Ibhulashi eliqinile kanye netafula lokusebenza elixutshwe nebhola linciphisa umsindo nokudlidliza ngesikhathi sokugijima futhi livikela ingaphezulu leshidi.

6. Uhlaka oluhlanganisiwe lwe-O-type lunyakazisiwe kabili, ukucindezeleka kususwe ngokuphelele. Uhlaka lucutshungulwa isikhungo sokucubungula i-pentahedron yaseJalimane i-SHW ezinhlangothi ezimbili ngesikhathi esisodwa, asikho isidingo sokwenza ukuma okwesibili.

7. I-clamp entantayo enamandla amakhulu e-clamping iqinisekisa ukudla okuzinzile; inqola ehlanganisiwe iqinisekisa ukuqina okuhle kanye nokunyakaza okulula kwe-clamp.

8. Uhlelo lufakwe nomsebenzi wokuvikela i-clamp othomathikhi ukugwema ukulimala kwethuluzi kanye ne-clamp, ukuqinisekisa ukusebenza okuqhubekayo kohlelo.

9. Inkomba ye-auto-index isebenzisa isondo lezikelemu elinembe kakhulu nendlela yezikelemu, iqinisekisa ukukhonjwa okuphezulu okunembayo. UMax. ububanzi bamathuluzi bungafinyelela ku-88.9mm futhi inkomba ye-auto-index inganwetshwa ibe ngu-4 nos.

10. Isakhiwo se-beam esihlanganisiwe sokwenza inqola kanye ne-beam ibe yingxenye eyodwa, okwandisa ukuqina futhi kuletha ukuma okunembile. Umshini ungasebenza kahle kakhulu ngesikhathi sokuphakelwa ngesivinini esiphezulu futhi uqeda ukuchezuka kwezimbazo ezingu-X no-Y.

11. I-X axis: isebenzisa i-servo motor ukuze ishayele abasebenzi bamabhola anembayo ephezulu futhi inqola ifakwe enokuqina okuphezulu nomklamo ongasindi. I-axis ye-Y: I-servo motor ishayela ngokuqondile i-rack yokudla exhunywe nomzila womshini, insimbi yohlobo oluhlukanisiwe ihlanganiswe ne-recking rack, futhi amandla okubamba azodluliselwa kuhlaka lomshini & emhlabathini nge-rack yokudla kanye nomhlahlandlela ukuze kuncishiswe ukudlidliza kwe-beam. Lesi sakhiwo sibonakala ngezici zokuqina okuhle, isisindo esilula, amandla adonsela phansi aphansi, kanye nokusabela okuhle okuguquguqukayo kulo lonke uhlelo lokudla, ukugijima okuzinzile nokunemba okuhle.

12. Isistimu yokugcoba emaphakathi iyamukelwa ukuthumela amafutha okugcoba endaweni yokugcoba ehlobene ngokuqondile, ukunciphisa ukungqubuzana kwamapheya asebenzayo futhi kwandise impilo yesevisi.

13. I-anti-sheet-deformation switch kanye ne-sheet-anti-stripping switch iyamukelwa.

| Cha. | Igama | Qty. | Phawula |

| 1 | Uhlu lokupakisha | 1 isethi | |

| 2 | Isitifiketi Sekhwalithi | 1 isethi | |

| 3 | Imanuwali Yokusebenza kukaMechanic | 1 isethi | |

| 4 | Imanuwali Yokusebenza Kagesi | 1 isethi | |

| 5 | Umdwebo wesisekelo | 1 isethi | |

| 6 | Umdwebo Oyinhloko Kagesi | 1 isethi | |

| 7 | Uhlelo oluzenzakalelayo lwemibhalo Yesistimu Yesoftware | 1 isethi | |

| 8 | DBN Electrical Umdwebo Umdwebo | 1 isethi | |

| 9 | Imanuwali yamathuluzi | 1 isethi | |

| 10 | Imanuwali yesistimu ye-CNC | 1 isethi | |

| 11 | Tooling Umdwebo | 1 isethi |

| Cha. | Igama | Isilinganiso | Qty. |

| 1 | I-Dual-head Spanner | 5.5×7-22×24 | 1 isethi |

| 2 | I-Spanner Enyakazayo | 200 | 1 no. |

| 3 | I-Socket Head Spanner | I-S1.5-S10 | 1 isethi |

| 4 | I-Cross Screwdriver | 100×6 | 1 no. |

| 5 | Gcoba Gun | I-HS87-4Q | 1 no. |

| 6 | Gcoba Lubrication Pump Compressor Gun | I-SJD-50Z | 1 no. |

| 7 | Isibhamu esiphezulu | 1 isethi | |

| 8 | I-T shape knob | M14×1.5 | 1 no. |

| 9 | Indlela yokushintsha | I-M12 PNP SN=2 ivuliwe | 1 isethi |

| 10 | Indlela yokushintsha | I-M12 PNP SN=2 vala | 1 no. |

| 11 | I-Spanner | T09-02,500,000-38 | 1 no. |

| 12 | Isipana sokushintshwa kwesilinda segesi | 1 isethi | |

| 13 | Ipayipi elithambile | Ø 12 | 1 no. |

| 14 | Iphinikhodi yepayipi elithambile | I-KQ2H12-03AS | 1 isethi |

| 15 | Izingxenye zesisekelo | 1 no. |

| Cha. | Igama | Isilinganiso | Qty. | Phawula |

| 1 | Ibhodi legiya lokubamba | 3 nos. | T02-20A.000.000-10C T02-20A.000.000-24A | |

| Ibhodi le-clamp portective | 6 noz. | T02-20A.000.000-09C Noma T02-20A.000.000-23A | ||

| 2 | I-Spring Small screw in clamp | M4x10 | 20 no. | T02-06,001,000-02 |

| M5x12 | ||||

| 3 | isikulufu ku-clamp Isikulufu sangaphakathi | M8 x 1 x 20 | 20 no. | |

| 4 | I-blade yokugunda | 30T | 2 no. | T09-16.310,000-0.1.2 |

| 5 | Isikulufu sangaphakathi | M8 x 1 x 20 | 4 nos. |

Uhlelo lwe-FANUC CNC wuhlelo olukhethekile lwe-CNC olwakhiwe yi-Japan FANUC ikakhulukazi ngenhloso yokuhlangabezana nezici zalolu hlobo lomshini, ukuthuthukisa ukwethembeka komshini ngezinga elikhulu.

I, Izimpawu Zesistimu

1. Umsebenzi we-Graphic kanye ne-punch;

2. Uhlelo olulula lwekhodi ye-G ukuze lusebenze kalula;

3. Ichweba elijwayelekile le-Universal RS232 ukuxhumana nekhompyutha kalula;

4. Okuthuthukisiwe okugcwele kwe-digital servo motor kanye nesistimu ye-servo;

5.10.4″ Isibonisi esimibalabala se-LCD;

6. Impendulo yesifaki khodi se-Pulse semi-loop;

7. Inkumbulo ye-EMS: 256K;

8. Uhlelo lwenkundla, uhlelo lwehhovisi;

9. Isibonisi sesiShayina nesiNgisi;

10. Umsebenzi wokulingisa okuyingcaca;

11.Ikhadi elilodwa le-PCMCIA elinomthamo omkhulu wokulondoloza ipharamitha yesistimu, umdwebo wesitebhisi nohlelo lokucubungula, nokuqaphela inqubo ye-inthanethi yohlelo olukhulu lokucubungula umthamo;

12. Ukwenyuka kweyunithi encane kakhulu, isilawuli sokuthola indawo yesikhangiso se-servo ukuze kubonakale isivinini esikhulu nokusebenza okunembile okuphezulu;

13. Inkinobho yokusebenza kuphaneli ingachazwa ngokwemfuneko yangempela;

14. Izintambo zedatha ze-clutch ezinesivinini esikhulu ezinoxhumo oluncane lwekhebula;

15. Ukuhlanganiswa okuphezulu, isofthiwe ekhethekile. Isikhathi esifushane sokuqalisa, idatha ngeke ilahleke uma amandla eshoda ngokuphazima kweso;

16. Ukugcinwa kwezingcezu ezingama-400 zohlelo.

1. Izimbazo eziwumugqa: X, ama-eksisi Y, ama-eksisi ajikelezayo: T, C ama-eksisi, i-punch axis: I-eksisi Z;

2. I-alamu yephutha likagesi njengokushaywa unhlangothi ngokweqile.

3. Umsebenzi wokuzihlola.

4. Umsebenzi womkhawulo othambile.

5. Ikhodi ye-Universal G yohlelo;

6. Umsebenzi wokunxeshezelwa kwamathuluzi;

7. Umsebenzi wesinxephezelo sebanga lesikulufa;

8. Umsebenzi wokunxeshezelwa kwegebe elihlehlayo;

9. Umsebenzi wokuchezuka kwezixhumanisi;

10. Umsebenzi wokubekwa kabusha;

11. Umsebenzi we-AUTO, MANUAL, JOG mode;

12. Umsebenzi wokuvikela i-clamp;

13. Umsebenzi wokukhiya irejista yangaphakathi;

14. Umsebenzi wohlelo lwepharamitha;

15. Umsebenzi wohlelo oluncane;

16. Umsebenzi we-swift positioning kanye ne-punch lock;

18. Umsebenzi wekhodi engu-M;

19. Uhlelo oluphelele nolukhulisayo;

20. Conditioning, unconditioning jump.

Isethulo sesoftware yokuhlela

Samukela i-CNCKAD evela ku-METALIX Company. Isofthiwe iyisethi ephelele yesofthiwe yokuhlela ezenzakalelayo ye-CAD/CAM kusukela ekwakhiweni kuya ekukhiqizweni. Ngokuphathwa komtapo wesikhunta, ukucutshungulwa kwemodi ezenzakalelayo, ukwenziwa kahle kwendlela neminye imisebenzi, kungenziwa ngokuzenzakalelayo ngezinqubo zokucubungula ze-CAD zomdwebo we-NC. Ungakwazi ukufeza uhlelo olulodwa, ukwenza isidleke okuzenzakalelayo kanye nephakheji eliphelele.

Umsebenzi we-DrawingCNCKAD ihluzo ezinamandla, kulula futhi enembile ukuyisebenzisa, ngaphezu komsebenzi ojwayelekile wokudweba ngokwezici zensimbi yeshidi, wengeze ezinye izindlela ezikhethekile zokudweba ezifana nokusikwa, nxazonke, unxantathu, i-angle engakwesokudla kanye nokuma kwe-contour, ukuxova, ukuhlola ukuhlela nokulungiswa okuzenzakalelayo, ukusika noma ukunyathela, izinhlamvu zesiShayina DXF/IGES/CADL/DWG okokufaka kwefayela njll.

b) Umsebenzi Wokubhoboza

Ifakwe nesibhakela esizenzakalelayo, isikhunta esikhethekile, ukukhomba okuzenzakalelayo, ukuthutha okuzenzakalelayo, ukusika umphetho, neminye imisebenzi.

c) Umsebenzi Wokugunda

Hlola i-contour ezenzakalelayo futhi ulungise amapharamitha ohlobo lwezinto ezibonakalayo, ukujiya, ukusikwa okukodwa, ukusika, nokususwa kwe-shear, neminye imisebenzi, ukucubungula kwepuleti lokugunda okuzenzakalelayo.

d) Ukucutshungulwa kokuthunyelwe

Ukucubungula okuzenzakalelayo noma okusebenzisanayo kuhlanganisa yonke inqubo: ukugxiviza, i-laser, iplasma, umlilo, ukusika amanzi nokugaya.

Ukucutshungulwa kokuthunyelwe okuthuthukisiwe kungakhiqiza zonke izinhlobo zekhodi ye-NC esebenzayo, indlela engaphansi yokusekelwa, uhlelo olukhulu, njengokwenza kahle kwendlela yamathuluzi kanye nokujikeleza okuncane kwesikhunta, umjovo wokusekela, imisebenzi yomshini wokudonsa i-vacuum efana nenani lempahla kanye ne-sliding block.

Dlulisela uhlelo komunye umshini udinga nje ukuchofoza okumbalwa ngegundane.Lokhu kuthathwe endleleni yokucubungula okuthunyelwe kwe-CNCKAD, ngokususa amafayela ekhompiyutha amaningi enza umsebenzi usebenze kakhulu.

e)CNC Ukulingisa Graphical

I-Software isekela noma yikuphi ukulingisa okuyingcaca kohlelo lwe-CNC, okuhlanganisa nekhodi ye-CNC ebhalwe ngesandla, inqubo yokuhlela nayo ilula kakhulu, isofthiwe ingahlola ngokuzenzakalelayo amaphutha, njenge-clamp yemingcele elahlekile namaphutha webanga, njll.

f) Ukuguqulwa kusuka ku-NC kuya ku-Drawing

Kuphakathi kokuthi ngesandla esibhaliwe noma enye ikhodi ye-NC, ingashintshwa ibe izingxenye zehluzo.

g) Umbiko Wosuku

Ingakwazi ukuphrinta umbiko wedatha, okuhlanganisa lonke ulwazi olufana nenani lezingxenye, ukucubungula ulwazi olufana nesikhathi, isethi yesikhunta njll.

h) Ukudluliselwa kwe-DNC

Ukwamukela isixhumi esibonakalayo seWindows semojula yokudlulisa, ukuze ukudluliselwa phakathi kwe-PC nemishini yomshini kube lula kakhulu.

1) 、 Sekela wonke amamodeli we-CNC turret punch, umshini wokusika we-laser, umshini wokusika i-plasma nomshini wokusika amalangabi namanye amathuluzi omshini.

2)、Sekela yonke inqubo yokusebenza kwemishini ye-CNC, okuhlanganisa ukudweba, ukucubungula okuzenzakalelayo noma okusebenzisanayo, ukucubungula okuthunyelwe, uhlelo lokulingisa lwe-CNC, ukusika okwenziwa ngesandla nokuzenzakalelayo, ukulanda nokulayishwa kwefayela le-NC njll.

3)), Ingakwazi ukufaka ngokuqondile i-Autocad, i-SolidEdge, i-SolidWork ne-CadKey njll kuhlanganise nayo yonke isofthiwe edumile ye-CAD ekhiqizwe ifayela lehluzo.

4) 、 Isoftware isekela izinhlobo ezahlukene zemishini yokulawula izinombolo, ingabeka izingxenye ze-NC zikhiqize amafayela wemishini ehlukene, kumadivayisi amaningi ngasikhathi sinye ngesikhathi sokucubungula.

Ukubeka kabusha Okuzenzakalelayo

Uma usayizi wepuleti mkhulu kunobubanzi obuthile, umshini uzibeka kabusha ngokuzenzakalelayo, bese ukhiqizwa ngokuzenzakalelayo imiyalelo yokuma; uma umsebenzisi enezidingo ezikhethekile, zingashintshwa noma zisuswe ngokwazo imiyalelo yokubeka kabusha.

Ukugwema ukugoqa okuzenzakalelayo

Imiyalo eyenziwe ngokubeka ngokuzenzakalelayo okungenza i-clamp igweme indawo efile, inciphise imfucuza; kungakhathaliseki ukuthi ipuleti liyingxenye noma izingxenye ezimbalwa zepuleti lensimbi, lingabona ukusebenza kokugwema i-clamp.

I-strip material processing

Ukuze kuncishiswe ukuguqulwa kwezinto enqubweni yokugxiviza, indlela yokucubungula impahla ye-strip ingamukelwa, futhi ithuluzi lokusika lingasetshenziswa ngaphambili noma ngemuva komyalelo wegatsha.

Indlela yokuthena

Kuhlanganiswe nomsebenzi wokubhoboza onqenqemeni okuvamile, ukubhoboza okuzenzakalelayo okukwazi ukushaya into ephukile emaphethelweni.

I-Single calmp ihamba ngokuzenzakalelayo

Ngomshini wokuqinisa oshukumayo kungenziwa isofthiwe ehamba ngokuzenzakalelayo i-clamp ngokusebenzisa imiyalelo ye-NC.

Ukuzungezisa okuncane kokufa

Inketho encane yokuzungezisa inganciphisa ukuguga kwesiteshi senkomba esizenzakalelayo futhi ithuthukise ukusebenza kahle kokukhiqiza.

Umsebenzi Wezinhlobo Eziningi Zokubhoboza

Umsebenzi wokubhoboza unxantathu, ukubhoboza kwe-bevel, ukubhoboza kwe-arc kanye nezinye indlela eyingqayizivele nephumelelayo yokushaya.

Umsebenzi Wokushaya Okuzenzakalelayo Okuqinile

Izici ze-Punching ezizenzakalelayo zifaka ukuxhumana okuzenzakalelayo okuncanyana, ukukhetha okuhlakaniphile kwesikhunta kanye nengcebo yokutholwa kwe-alamu neminye imisebenzi.

I) Umsebenzi wokusika ngokuzenzakalelayo

I-METALIX CNCKAD iqukethe ingxenye ye-AutoNest okuyisethi yesofthiwe yokuzalela yepuleti yangempela ezenzakalelayo, ekwazi ukubona konke ukwenziwa ngcono kweshidi lensimbi yendlela yobuchwepheshe.

1. Ukunikezwa komoya: ingcindezi yokusebenza elinganiselwe kufanele ibe ngaphezu kuka-0.6mPa, ukugeleza komoya: ngaphezu kuka-0.3m3/min

2. Amandla: 380V, 50HZ, amandla ashintshashintshayo: ±5%, amandla kagesi we-30T ngu-45KVA, ububanzi bekhebula eliguqukayo ngu-25mm², i-breaker ngu-100A. Uma ukunikezwa kwamandla kungazinzile, i-stabilizer iyadingeka, uma kukhona ukuvuza kagesi, ukuvikelwa kuyadingeka.

3. Uwoyela we-Hydraulic: (SHELL) I-Tonna T220, Noma omunye uwoyela wokugcotshwa komhlahlandlela kanye nesitimela.

Amafutha okugcoba: 00 # -0 # I-Gree pressure grease (GB7323-94), isiphakamiso: ngaphansi kwe-20 ° C sebenzisa 00 # I-Gree pressure grease, ngaphezu kwe-21 ° C sebenzisa 0 # I-Gree pressure grease

| Ibhrendi | Igama | Ukuphawula | Izinga lokushisa |

| Igobolondo | I-EPO | 0# Amafutha okucindezela okukhulu | 21°C ngaphezulu |

| Igobolondo | I-GL00 | 00 # Amafutha okucindezela okukhulu | 20°C ngaphansi |

3. Izinga lokushisa lendawo: 0°C - +40°C

4. Umswakama wendawo: umswakama ohlobene 20-80%RH(un-condensation)

5. Gwema ukudlidliza okuqinile noma ukuphazamisa uzibuthe kagesi

6. Imvelo enothuli oluncane, ayikho igesi enobuthi

7. Lungiselela isisekelo ngokomdwebo wesisekelo

8. Umsebenzisi kufanele akhethe uchwepheshe noma unjiniyela ozoqeqeshwa, isizinda sakhe semfundo okufanele okungenani athole iziqu esikoleni samabanga aphakeme obuchwepheshe, futhi asihlelele isikhathi eside.

11.Kumelwe alungise isisekelo ngokomdwebo

12. Isipane sokuvula esingu-65mm, induku esekela i-afterburner, ukulungisa izinga lesisekelo.

13. Ngaphezu kwamalitha angu-5 kaphethiloli ohlanzekile, inqwaba yamanikiniki, isibhamu, uwoyela wokugcoba, cishe ilitha elingu-1 lamathuluzi omshini wokukhuhla kanye nesikhunta.

14 nge-Ф10*300 eyodwa kanye ne-Ф16*300 izinti zethusi zokufakwa kwesikhunta. Ugongolo olude (i-fuselage ne-beam kuhlanganiswa ngokwehlukana, kodwa futhi nokulungisa amayunithi athunyelwe)

15 inkomba yokudayela (ububanzi obungu-0-10mm), esetshenziselwa ukulungisa iphutha le-eksisi engu-X kanye ne-Y.

16 lapho okokusebenza kufika efekthri, lungiselela ithrafikhi engu-20T noma i-crane yezinto zokuphakamisa

17.Uma i-V axis ifakwe injini yokupholisa amanzi, i-median yokupholisa ehlobene kufanele ilungiswe, ivolumu ingu-38L.

Ezinye izindaba ezingakhulunywanga zidinga ukuhunyushwa okwengeziwe nokuxhumana

Umshini we-CNC Turret Punch; umshini we-turret punch; umshini we-cnc wokubhoboza; umshini wokubhoboza we-turret; i-cnc punch press; cnc turret punch press; cnc punch punch; umshini we-punch uyathengiswa; umshini we-turret punch cindezela; umshini we-cnc punch cindezela umshini;izinombolo zokulawula i-turret punch press;i-servo drive turret punch press;i-turret punch press iyathengiswa

| Cha. | Ukucaciswa | Iyunithi | Imodeli Yomshini | ||

| I-MT300E | |||||

| 1 | Ubukhulu. Punch Force | kN | 300 | ||

| 2 | Uhlobo Lokushayela Oluyinhloko | / | Ihamba ngemoto eyodwa | ||

| 3 | Uhlelo lwe-CNC | / | Uhlelo lwe-FANUC CNC | ||

| 4 | Ubukhulu. Usayizi Wokucubungula Ishidi | mm | 1250*5000 (ngokubekwe kabusha okukodwa) | 1500*5000 (ngokubekwe kabusha okukodwa) | |

| 5 | Inombolo ye-Clamp | cha. | 3 | ||

| 6 | Ubukhulu. Icubungula Ukuqina Kweshidi | mm | 3.2/6.35 | ||

| 7 | Ubukhulu. Punch Diameter Isikhathi ngasinye | mm | Φ88.9 | ||

| 8 | I-Main Striker Stroke | mm | 32 | ||

| 9 | Ubukhulu. I-Punch Hit nge-Pace engu-1mm | hpm | 780 | ||

| 10 | Ubukhulu. Punch Hot at 25mm Pace | hpm | 400 | ||

| 11 | Ubukhulu. Nibbling Speed | hpm | 1800 | ||

| 12 | Inombolo Yokumisa Kabusha Isilinda | setha | 2 | ||

| 13 | Inombolo Yesiteshi | cha. | 32 | ||

| 14 | Inombolo ye-AI | cha. | 2 | ||

| 15 | Inombolo ye-Eksisi Yokulawula | cha. | 5(X,Y,V,T,C) | ||

| 16 | Uhlobo Lwethuluzi | / | Uhlobo Olude | ||

| 17 | Uhlobo Lokusebenza | / | Ngaphansi kuka-3.2mm: Ibhulashi eligcwele elinethebula lokusebenza elingaguquki (Amabhola okuphakamisa ukulayisha anganezelwa njengenketho) | ||

| Ngaphezulu kuka-3.2mm: Amabhola agcwele asebenzayo | |||||

| 18 | Ubukhulu. Isivinini Sokudla | I-X eksisi | m/min | 80 | |

| Y ekseni | 60 | ||||

| XY Ihlanganisiwe | 100 | ||||

| 19 | Isivinini se-Turret | rpm | 30 | ||

| 20 | Isivinini Sokuzungezisa Amathuluzi | rpm | 60 | ||

| 21 | Ukunemba | mm | ±0.1 | ||

| 22 | Ubukhulu. Layisha Amandla | Kg | 100/150 yebhola worktable | ||

| 23 | Amandla Ezimoto Eziyinhloko | kVA | 45 | ||

| 24 | Imodi yamathuluzi | / | uhlobo oluzimele lwe-disassembly olusheshayo | ||

| 25 | Ingcindezi Yomoya | I-MPa | 0.55 | ||

| 26 | Ukusetshenziswa Komoya | L/ min | 250 | ||

| 27 | CNC Memory Amandla | / | 512k | ||

| 28 | Bamba ukutholwa kwendawo efile | / | Y | ||

| 29 | Ishidi lokunqamula ukuhlubula | / | Y | ||

| 30 | I-Anti-Sheet-Deformation Switch | / | Y | ||

| 31 | I-Outline Dimension | mm | 5350×5200×2360 | 5850×5200×2360 | |

| Cha. | Igama | Ibhrendi | Isilinganiso | ||

| 1 | Uhlelo lwe-CNC | I-FANUC | I-OI-PF | ||

| 2 | I-Servo Driver | I-FANUC | I-AISV | ||

| 3 | I-Servo Motor (X/Y/C/T axis) | I-FANUC | I-AIS(X,Y,T,C) Injini ekhethekile ye-V axis | ||

| 4 | Umhlahlandlela | THK | I-HSR35A6SSC0+4200L (X:2500) | ||

| I-HSR35A3SSC1+2060L-Ⅱ (Y:1250) | |||||

| I-HSR35A3SSC1+2310L-Ⅱ (Y:1500) | |||||

| 5 | I-Ballscrew | THK | BLK4040-3.6G0+3016LC7 (X:2500) | ||

| BLK3232-7.2ZZ+1735LC7T (Y:1250) | |||||

| BLK3232-7.2ZZ+1985LC7T (Y:1500) | |||||

| 6 | Ukuzala Okuqondile | NSK/Koyo | 25TAC62BDFC10PN7B/SAC2562BDFMGP4Z | ||

| 30TAC62BDFC10PN7B/SAC3062BDFMGP4Z | |||||

| 7 | Izingxenye zomoya | Okuthathu okuhlangene | I-SMC | I-AC30A-03D | |

| I-valve ye-Solenoid | I-SY5120-5D-01 | ||||

| I-Muffler | I-AN10-01 | ||||

| Isilinda | I-CP96SDB40-80-A93L | ||||

| 8 | Uhlelo lukagesi | Umaphuli | Schneider | / | |

| Oxhumana naye | Schneider | / | |||