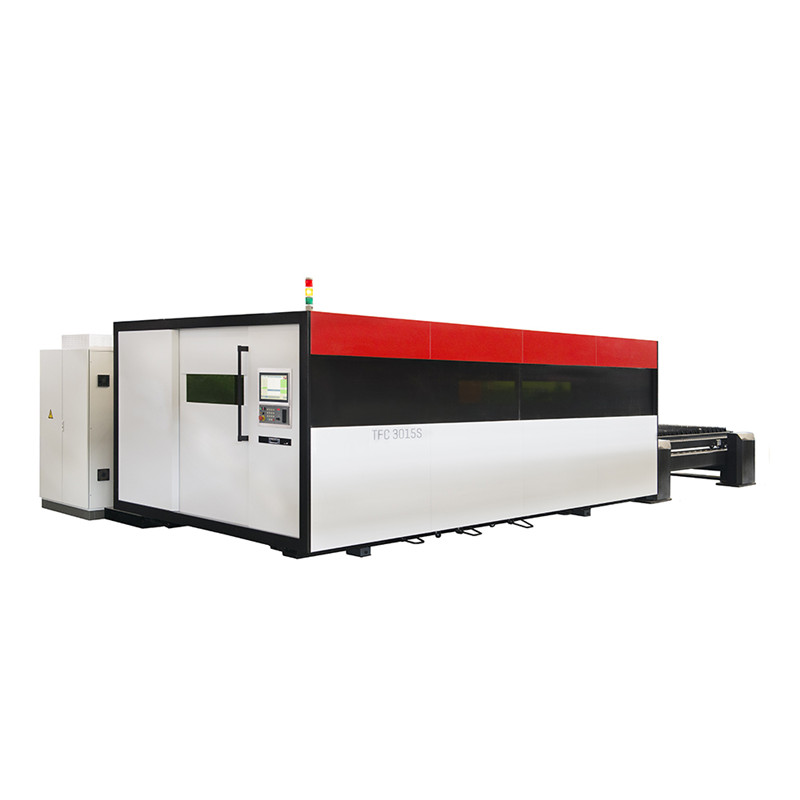

I-CNC Fiber Laser Cutting Machine

Umshini wokusika we-laser we-EFC3015 CNC usetshenziselwa ikakhulukazi ukusika nokucutshungulwa kwepuleti eliyisicaba, ngohlelo lwe-CNC, umugqa oqondile kanye nejika lokuma ngendlela engafanele lingasika futhi liqoshwe epuletini. Ingakwazi ukusika kalula ipuleti lensimbi elivamile le-carbon, ipuleti lensimbi engagqwali, ipuleti lethusi, ithusi eliphuzi ne-aluminium, nenye insimbi engakwazi ukusikwa kalula ngendlela evamile yokucubungula.

I-EFC3015 CNC laser cutting machine iwuhlobo olusha lomshini wokusika we-laser. Isakhiwo sinokuqina okuphezulu, ukuzinza okuhle, ukusebenza kahle kokusika okuphezulu kanye nokunemba okuphezulu kwemishini. Imikhiqizo inokuguquguquka okuphezulu, ukuphepha, ukusebenza okulula nokusetshenziswa kwamandla aphansi. Ingowomkhiqizo wokuvikela imvelo, usayizi wepuleti ocutshunguliwe: 3000 * 1500mm; ngesivikelo sokuphepha kanye netafula le-shuttle. Isakhiwo sonke sihlangene futhi sinengqondo.

Ukusetshenziswa okuphansi - i-laser ayidingi igesi;

Ukusetshenziswa kwamandla okuphansi, ukonga amandla, ukuvikelwa kwemvelo, ukusetshenziswa kwamandla okuphansi;

Isakhiwo se-modular, isistimu yokupholisa kanye nesistimu yomthombo wokukhanya kanye nomthombo we-laser kuhlanganiswe ndawonye;

Ukuzinza okuphezulu - amandla - uhlelo lokulawula impendulo yesikhathi namandla we-laser, ukuqina kwamandla 1%;

Izindleko zokulungisa ziphansi - i-fiber head isebenzisa ubuchwepheshe bokuvikela isibuko, uma ingcolile, idinga kuphela ukushintsha ilensi yokuvikela;

A. yamukela inkomba yomugqa enembile engenisiwe, ngenisa idrayivu yokubeka igiya enembile, iqinisekisa ukunemba kokuma nokuphindaphinda.

B. I-Gantry yohlobo lwe-dual motor direct drive structure yenza ukuthi sonke isakhiwo somkhiqizo sihlangane, futhi ukuqina kuhle, futhi ukuphakama kwawo wonke umshini kuphansi.

Umzimba oyinhloko ushiselwe ngamapuleti ensimbi, emva komshini onzima, obhekene nokucindezeleka kokuguga. Ngokusebenzisa imishini enembile, inikeza inkundla eqinile kanye nezinga lesistimu yokunyakaza.

I-beam isebenzisa ukwakheka okuguquguqukayo, nomsebenzi wokunwebeka oguqukayo kanye nomsebenzi wokufinyeza, ukubala ngokusebenzisa indlela yesici esilinganiselwe. Izingxenye ze-beam zigxunyekwe embhedeni ngomhlahlandlela oqondile wokugoqa. Umhlahlandlela, igiya kanye nendawo yokubeka kufakwe isembozo sokuzivikela esiguquguqukayo, ukuze ugweme ukungcoliswa uthuli.

Umkhiqizo ufakwe i-shuttle worktable, kulula ukuyilayisha futhi ilayishe impahla uma usika. Ngezansi kwetafula lokusebenza elifakwe izingxenye zokuhlukanisa uthuli kanye nomsele wokuqoqa impahla, ohambisana nemoto yokukhipha isondo, izinsalela zingangena ngqo emotweni yokulahla udoti.

I-fiber laser inezici ze-spectroscopy eseduze ne-infrared, ikhwalithi ye-beam ephelele, ukuhanjiswa kwe-fiber optical, ukusebenza kahle okuphezulu kokuguqulwa kwe-electro-optical nokunye.

(1) Ngomsebenzi wokubonisa ukukhanya kwelaser ebomvu.

(2) Ukusebenza kahle kakhulu kokuguqulwa kwe-electro-optic: ukusebenza kahle kokuguqulwa kwe-fiber laser electro-optic cishe kungama-33%.

(3) Umthombo wephampu ye-fiber laser wenziwe ngemojula yamandla aphezulu e-single core semiconductor, futhi isikhathi sokuhluleka esimaphakathi sincane.

(4) Ukusebenza kahle okuphezulu, isici sokushisa sangaphakathi siphansi kakhulu uma kuqhathaniswa ne-laser yendabuko, isidingo samandla kagesi nokupholisa siyancipha kakhulu.

(5) I-laser generator ayidingi igesi esebenzayo, ikhona kwilensi ngaphakathi futhi ayidingi ukuyigcina, ayidingi isikhathi sokuqala.

(1) Uhlelo lokulawula lwe-CNC lusebenzisa i-Windows 7system, ukusebenza kuzinzile futhi kuthembekile.

(2) I-torque enkulu ye-AC yedijithali ye-servo motor yokuqinisekisa ukuthi ukunemba kokuma komkhiqizo nokusebenza okunamandla.

(3) Ukulingiswa kwezithombe.

(4) umsebenzi wokulawula amandla.

(5) Umsebenzi we-Leapfrog.

(6) Ukusika umsebenzi wokuskena.

(7) Umsebenzi wokucubungula obukhali.

(8) Misa isikhashana umsebenzi, urekhoda ngokuzenzakalelayo isigaba senqubo.

(9) Ukubuka kuqala kohlelo lwe-NC kungashintshwa ngesikhathi sangempela ukuze kulungiswe inqubo yokuhlela.

(10) Hlela, lungisa noma yimiphi imiyalelo ohlelweni lokusesha ukuze..

(11) umsebenzi wokuzihlola, okuhlukile kwe-alamu kuboniswa ku-interface yokusebenza.

(12) Ubukhulu be-workpiece bungakhuliswa futhi buncishiswe.

(13) Umsebenzi wokucubungula isithombe we-workpiece.

(14) Umsebenzi wokusesha onqenqemeni ozenzakalelayo.

(15) Ngemva kokucisha ugesi, izixhumanisi zamanje zingarekhodwa futhi zisethwe kabusha ngokuzenzakalelayo ngemva kokuba amandla avuliwe.

I-laser beam yenziwe nge-fiber optical, futhi i-laser beam ihambisana nelensi yokugxila. Ilensi yokuzivikela efakwe esihlalweni sesibuko "sohlobo lokudonsa", ukugcinwa kanye nesikhathi sokushintsha sifushane kakhulu. Khetha ikhanda le-laser cut with non-contact capacitive sensor, ukusebenza kuzinzile futhi kuthembekile, kulula ukuyisebenzisa.

Izici zimi kanje:

(1) Ukusetshenziswa kwamalensi okuvikela ohlobo lwekhabethe ukuze kube lula ukushintshwa ngokushesha kwamalensi okuvikela abonayo ukuze kuvikelwe ilensi ye-collimator kanye nelensi egxilile.

(2) Ikhanda lokusika lifakwe idivayisi yokulandelela ezenzakalelayo ye-axis engu-Z elawulwa inzwa ye-capacitive engathinteki. Enqubweni yokusika, isikhundla esihlobene phakathi kokugxila kwe-laser nepuleti singalungiswa ngokuzenzakalelayo ngebanga eliphakathi kobuso be-workpiece kanye nombhobho.

(3) Ikhanda lokusika i-laser linganikeza uhlelo lwe-CNC ngesignali yokuvula ikhebula kanye nokushayisana kwekhanda lokusika, njll.

(4) Ukucindezela kwegesi kwe-2.5 MPa kungenziwa ngaphansi kokusikwa kwezinto zokucubungula njengensimbi engagqwali.

(5) Amanzi apholile, ukusika igesi elisizayo, izinzwa, njll konke kuhlanganiswe ekhanda lokusika, ukunciphisa ngokuphumelelayo umonakalo ezingxenyeni ezingenhla kwinqubo yokusika, ukuthuthukisa ukuzinza komkhiqizo.

4.Idivayisi yokuphepha:

Indawo yokucubungula ivalwe ngesembozo sokuzivikela futhi ihlinzekwa ngefasitela lokuvikela ukuvikela umqhubi emisebeni ye-laser.

5.Ukuqoqwa kothuli:

Indawo yokusika ifakwe ipayipi lokuhlukanisa uthuli, futhi iqoqo eliqinile le-centrifugal lisetshenziselwa ukususa uthuli nothuli. Nikeza isiphephetha-moya kanye nosayizi wesixhumi esibonakalayo kanye nepayipi lamamitha angu-3, ishubhu lokunweba lenziwa umsebenzisi ngokwendawo yesehlakalo, ubude bepayipi lomoya bungaphansi kwamamitha ayi-10, isiphephetha-moya singaphandle;

6.Amandla okumelana nokuphazamiseka:

Ngesistimu yokulawula yedijithali ethuthukisiwe, inamandla okumelana nokuphazanyiswa. Uhlelo lukagesi lwamukela ngokuqinile ukwakheka kwe-anti-jamming, iKhabhinethi yokulawula kagesi ihlukaniswe izifunda eziqinile nezibuthakathaka, ezingavimbela ngokuphumelelayo ukuphazamiseka phakathi kwezingxenye zikagesi, ngakho-ke ingaqinisekisa ukusebenza okuthembekile nokuzinzile kwemikhiqizo.

7. Ukukhanyisa:

Indawo yokusika ifakwe amalambu kagesi amabili okuphepha, anganikeza ukukhanya lapho ukukhanya kunganele noma kugcinwa, okwenza ukusebenza kube lula.

8.Izingxenye zikagesi:

Izingxenye zikagesi ezisebenzisa i-Schneider neminye imikhiqizo eyaziwa kakhulu ye-Brand Company yamazwe ngamazwe, ithuthukisa kakhulu ukwethembeka kokusebenza. Ikhabhinethi kagesi yamukela isakhiwo esizimele esivaliwe, futhi umbala wocingo usetshenziselwa ukuhlukanisa i-AC, DC, amandla kanye nocingo oluyisisekelo oluvikelayo.

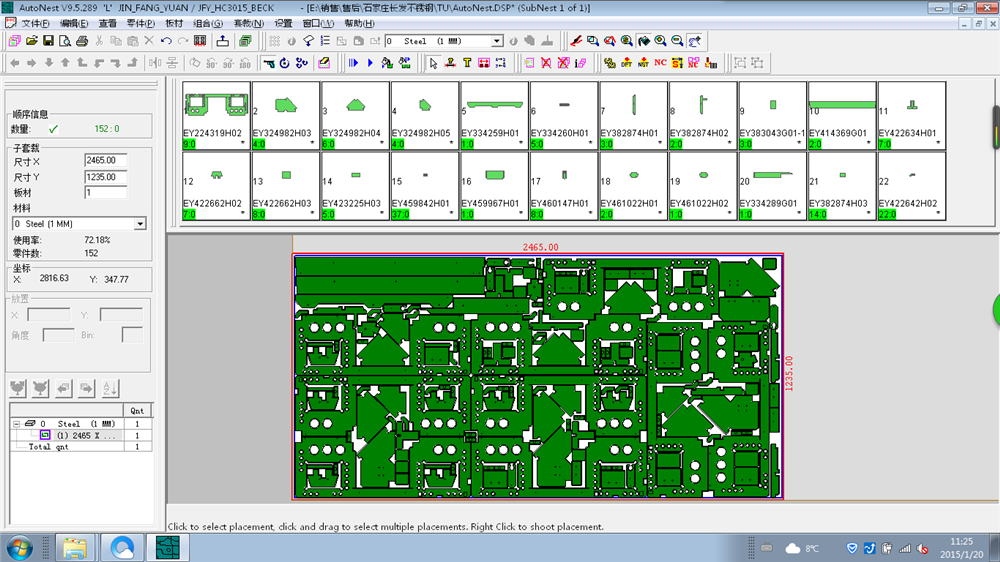

Umkhiqizo ofakwe isofthiwe yokuhlela ye-CNCKAD othomathikhi, awukwazi nje ukuxhunyaniswa nobuchwepheshe be-CAD/CAM yefekthri, kodwa futhi nokunciphisa umsebenzi wokuhlela kanye nokwenzeka kwephutha, uhlelo oluhle lungalinganisa ukusika. Ifakwe imojula yesakhiwo sokusika, ukwenza ngcono okuzenzakalelayo kanye nesakhiwo sezingxenye ezizokwenziwa ngomshini. Zombili ihluzo ezilula neziyinkimbinkimbi zomsebenzi zingaguqulwa ngokuzenzakalela zibe uhlelo lokucubungula.

Umsebenzi wesoftware wokuhlela we-NC laser cutting:

(1) Yonke i-interface esebenzayo yamaShayina.

(2) Ukusekelwa kwe-DWG, ifomethi ye-DXF yokufaka nokuphumayo.

(3) Ukusebenza kokuzihlola kuhle, yenqaba ukwenza ukusebenza kwephutha

(4) Umsebenzi wokuzalela ngokuzenzakalelayo, okonga okokusebenza.

(5) Umsebenzi wokusika ungqimba oluningi ozenzakalelayo ngokugcwele.

(6) Umsebenzi wokuqopha.

(7) Izinhlobonhlobo zefonti zase-UK nesiShayina.

(8) Ubude bephethini yokusika bungabalwa.

(9) Umsebenzi ojwayelekile wokusika umphetho.

(10) Imisebenzi yokuphatha izindleko.

(11) Ukusika imininingwane egciniwe..

(12) Ukushintshisana kwedatha kungenziwa ngesixhumi esibonakalayo se-USB noma se-RS232.

* Indawo yokusebenza yesoftware (ncoma umsebenzisi ukuthi asekele ihadiwe)

(1) Inkumbulo 256M

(2) I-hard drive 80G

(3) Isistimu yokusebenza ye-XP Windows

(4) TFT 17 "Isibonisi se-LCD

(5) 16X DVD CD-ROM

| Into | Qty. | Phawula/Umphakeli |

| Uhlelo lwe-CNC | 1 isethi | Beck Hoff |

| Shayela | 1 isethi | LUST Drive (X/Y axis)+PHASE motor (X/Y axis)+Delta drive kanye motor (Z axis) |

| I-Laser Generator | 1 isethi | I-TRUFIBER CUT |

| Igiya elinembile le-eksisi ye-X/Y | 1 isethi | GUDEL/ATLANTA/GAMBINI |

| Isikulufu sebhola esinembayo esingu-Z | 1 isethi | THK |

| Umhlahlandlela womugqa webhola we-X/Y/Z onembile | 1 isethi | THK |

| Motor for itafula Shuttle | 1 isethi | THUNGA |

| Izingxenye zomoya | 1 isethi | SMC, GENTEC |

| Ukusika Ikhanda | 1 isethi | I-PRECITEC |

| Isoftware yohlelo oluzenzakalelayo | 1 isethi | CNCKAD |

| Izingxenye zikagesi | 1 isethi | Schneider |

| I-Towline | 1 isethi | IGUS |

| Isipholile Samanzi | 1 isethi | TONGFEI |

| Cha. | Into | Ukucaciswa | Iyunithi |

| 1 | Amandla | 380/50 | V/Hz |

| 2 | Kudingeka ukusatshalaliswa kwamandla | 40 | kVA |

| 3 | Ukuzinza kwamandla | ±10% | |

| 4 | Ikhompyutha | RAM 256M/hard disk 80G, DVD | |

| 5 | I-oksijeni yokusika insimbi ye-carbon | Ubumsulwa kufanele bube ngaphezu kuka-99 .9% | |

| 6 | I-nitrogen yokusika insimbi engagqwali | Ubumsulwa kufanele bube ngaphezu kuka-99 .9% | |

| 7 | Amanzi okupholisa amanzi (amanzi acwecwe) | 100 | L |

| Ukusebenza: > 25μS/cm | μs | ||

| 8 | Amanzi ahlanzekile | 150 | L |

| 9 | Ukumelana nokunciphisa | ≤4 | Ω |

| 10 | Ukufakwa izinga lokushisa imvelo laser generator | 5-40 | ℃ |

| 11 | Ukufakwa kwemvelo umswakama we-laser generator | Ngaphansi kuka-70% | |

| 12 | Imfuneko yendawo yokufaka (imininingwane ingadluliselwa kumdwebo wesisekelo) | Ugqinsi lukakhonkolo lwesisekelo kufanele lube lukhulu kuno-250mm, ukucaba kufanele kube ngaphansi kuka-10mm njalo ngo-3m. Akufanele kube nokudlidliza ngaphakathi kwendawo yokufaka. | |

| Into | Qty. | Iyunithi |

| Ilensi yokuzivikela | 5 | I-PC. |

| Indandatho ye-Ceramic | 1 | Cha. |

| Ukusika umlomo wombhobho | 6 | Cha. |

| I-Spanner | 1 | Cha. |

Nikeza yonke imibhalo edingekayo neningiliziwe yezobuchwepheshe yokufaka, ukusebenza nokugcinwa

(1) Imiyalo Yemishini Yokusika I-Laser

(2) Idatha Yesistimu ye-CNC

(3) Umdwebo wesimiso sikagesi

(4) Imiyalo Yezipholile Zamanzi

(5) Isakhiwo Sokufaka

(6) Umdwebo wesisekelo

(7) Isitifiketi Sokufaneleka

(8) Ukufakwa, ukuthunywa nokwamukelwa

Ngemuva kokuthi umkhiqizo ufikile endaweni yokufaka yomsebenzisi, inkampani yethu izohlela abasebenzi abanolwazi esizeni somsebenzisi ukuze bafakwe, basebenzise kanye nokusika isampula nokucutshungulwa. Ukwamukelwa kokugcina kwenziwa esizeni somsebenzisi ngokwezinga lokwamukelwa kwenkampani yethu. Izinto zokwamukela zihlanganisa: ikhwalithi yokubukeka, ukucushwa kwengxenye ngayinye, ukunemba kokusika kanye nekhwalithi, imingcele yokusebenza, ukuzinza, ukuhlolwa kokusebenza, njll.

Inkampani yethu inesibopho sokufaka kanye nokugunyaza .Abasebenzisi badinga ukulungisa abasebenzi abadingekayo kanye nemikhiqizo yokuphakamisa. Abasebenzisi balungiselela izinto ezisetshenziswayo kanye nezinto eziyisampula zokusebenzisa.

Isinyathelo sokuqala

(1) Ukwamukelwa kokuqala kwemikhiqizo kwenziwa enkampanini yethu.

(2) Ukwamukelwa kwemikhiqizo kuzokwenziwa ngokuhambisana nesivumelwano sobuchwepheshe esisayinwe yizinhlangothi zombili.

(3) Ukuhlolwa kokubukeka komkhiqizo: ukwakheka kwamapayipi kufanele kube okunengqondo, kucocekile futhi kube kuhle, ukuxhumana okuthembekile; umfaniswano wendawo yopende kanye nomhlobiso omuhle; ukubukeka komkhiqizo ngaphandle kokungqongqoza nezinye iziphambeko.

(4) Ukuhlolwa kokucushwa komkhiqizo.

(5) Ukuhlolwa kwendawo kwekhwalithi yesampula yokusika.

Isinyathelo sesi-2 Ukwamukela

(1) Ukwamukelwa kokugcina komkhiqizo kwenziwa endaweni yomsebenzisi.

(2) Ukwamukelwa kwemikhiqizo kuzokwenziwa ngokwesivumelwano sobuchwepheshe esayiniwe kanye ne-oda lokwamukela lokunikezela, futhi impahla yokuhlolwa izohlinzekwa ngumsebenzisi. Uma umsebenzisi edinga ukwamukela imidwebo ye-workpiece ejwayelekile, sicela unikeze imidwebo evamile (inguqulo ye-elekthronikhi) kusengaphambili.

(3) Ngemva kokuphothulwa kokufakwa nokuthunywa, uma umkhiqizo usebenza ngokujwayelekile , uzophumelela ukuhlolwa kokwamukela. Ukuhlolwa kokugcina kokwamukela kuzothathwa njengokufanelekile futhi isikhathi sokuqinisekisa ikhwalithi sizoqala.

(1) Kudinga abaqeqeshwayo ukuba babe nesikole samabanga aphakeme noma imfundo ephakeme (ubuchwepheshe bokusebenza kukagesi bungcono kakhulu), ngesikhathi esifanayo, babe nolwazi oluthile oluyisisekelo lwekhompyutha, futhi babe nekhono ekusebenzeni kwekhompyutha.

(2) Ngemva kokufakwa kanye nokugunyazwa, inkampani yethu inesibopho sokuhlinzeka ngokuqeqeshwa kwamahhala endaweni yabasebenzisi izinsuku eziyi-7, ukuqeqesha isisebenzi esilungisa ugesi esi-1, ama-opharetha angu-2 kanye nomsebenzi wokulungisa imishini ongu-1. Futhi uqinisekise ukuthi abasebenzisi bangakwazi ukusebenza kahle komkhiqizo, ukusebenza okulungile namakhono okulungisa.

(3) Okuqukethwe kokuqeqesha: ukwakheka nokusebenza komkhiqizo, ukusebenza kwe-laser, ukusebenza, ukuhlela kwe-NC, ubuchwepheshe bokucubungula i-laser, ukugcinwa kwansuku zonke nezinye izici.

(4) Ukusekelwa okukhethekile kokuqeqeshwa: Abasebenzisi bangahlela ama-opharetha angu-2-3 kanye nabasebenzi bokulungisa ukuthi beze enkampanini yethu nganoma yisiphi isikhathi.

Ukuqeqeshwa kukhululiwe ezinkokhelweni zokuqeqesha.

Izindleko ezitholwe ngesikhathi sewaranti zizothwalwa yinkampani yethu, ngaphandle kwalezo ezenzeke ngenxa yokusetshenziswa okungafanele nokusebenza kwabasebenzisi.

Inkampani yethu ihlinzeka ngezinsizakalo zokunakekela kanye nezingxenye ezisele impilo yonke.

Isikhathi sokuqinisekisa ikhwalithi yomkhiqizo unyaka owodwa kanti isikhathi sesiqinisekiso sekhwalithi yelensi yokubona siyizinsuku ezingama-90. Umbhobho wokusika, ipuleti lezinyo elisekelayo, isici sokuhlunga, umzimba we-ceramic kanye ne-optical lens yizingxenye eziphuka kalula.

Qaphela: I-EFC inomsebenzi wokusika umoya (i-10 kg air compressor), kodwa ikhasimende kufanele lihlomise izingxenye ezilandelayo lilodwa.

CNC Fiber Laser Cutting Machine;cnc fibre laser cutting machine;cnc fibre laser;cnc fibre laser cutter;cnc turret punch press abakhiqizi

| Into | Igama | Ibhrendi | Imodeli | OTY |

| 1 | I-compressor yomoya engenawo uwoyela | WW-0.9/1.0 | 1 | |

| 2 | Isomisi | PARKER | I-SPL012 | 1 |

| 3 | Isihlukanisi samanzi | domnick | I-WS020CBFX | 1 |

| 4 | Hlunga | domnick | I-AO015CBFX | 1 |

| 5 | Hlunga | domnick | I-AA015CBFX | 1 |

| 6 | Hlunga | domnick | I-ACS015CBMX | 1 |

| 7 | Ukuhlanganisa | PARKER | I-FXKE2 | 2 |

| 8 | Ukuhlanganisa | PARKER | I-NJ015LG | 1 |

| 9 | I-valve yokunciphisa ingcindezi | I-FESTO | LR-1/2-D-MIDI | 1 |

| 10 | Okuhlangene | I-SMC | I-KQ2H12-04AS | 1 |

| 11 | Okuhlangene | I-SMC | I-KQ2L12-04AS | 6 |

| 12 | Okuhlangene | I-SMC | I-KQ2P-12 | 1 |

| 13 | Ipayipi legesi | I-SMC | I-T1209B | 15m |

| 14 | Okuhlangene | EMB | I-VADKO 15-RL/WD | 1 |

| 15 | Okuhlangene | EMB | X A15-RL/WD | 1 |

1. Ukucaciswa Okuyinhloko

| Into | Ukucaciswa | Iyunithi | |

| 1 | Usayizi Wokusika Ishidi | 3000×1500 | mm |

| 2 | Ukushaywa kwe-X Axis | 3000 | mm |

| 3 | Ukushaywa kwe-Y Axis | 1500 | mm |

| 4 | Ukushaywa kwe-Z Axis | 280 | mm |

| 5 | Ubukhulu. Isivinini Sokudla | 140 | m/min |

| 6 | Ukunemba Ukusika | ±0.1 | mm/m |

| 7 | Ilinganiselwe Laser Power | 1000 | W |

| 8 | Ukuqina Kokusika (lapho isimo sokusika esidingekayo sifinyelelwa) | I-Carbon Steel 0.5-12 | mm |

| Insimbi engagqwali 0.5-5 | mm | ||

| 9 | Ukuqina Ukusika Okuzinzile | Insimbi ye-Carbon 10 | mm |

| Insimbi Engagqwali 4 | mm | ||

| 10 | Amandla Okufaka | 31 | kVA |

| 11 | Isikhathi sokushintshanisa ithebula le-Shuttle | 10 | S |

| 12 | Isisindo Somshini | 8 | t |

2.SPI Laser Resonator

| Imodeli | I-TruFiber -1000 |

| Amandla Okufaka | 3000W |

| Amandla Okukhiphayo | 1000W |

| I-Laser Power Stability | <1% |

| Ubude begagasi le-laser | 1075nm |

3.CNC Uhlelo

| Into | Ukucaciswa |

| Uhlelo lwe-CNC | Beckhoff |

| Iphrosesa | I-Dual-core 1.9 GHz |

| Umthamo wememori yesistimu | 4GB |

| Umthamo wememori yehadiwe | 8GB |

| Bonisa uhlobo lwesikrini nosayizi | 19″ umbala we-crystal liquid |

| Imbobo yokuxhumana ejwayelekile | I-USB2.0, i-Ethernet |