Isistimu Yokushintsha Umbala Esheshayo Ethuthukisiwe Enokuhlanza Okuzenzakalelayo Okuphumelelayo Nobuchwepheshe Bokugeleza komoya Okuphezulu

Impushana igcwaliswa ngokugcwele ebhokisini lempushana yebhakede lokuhlinzeka ngempushana, kanye ne

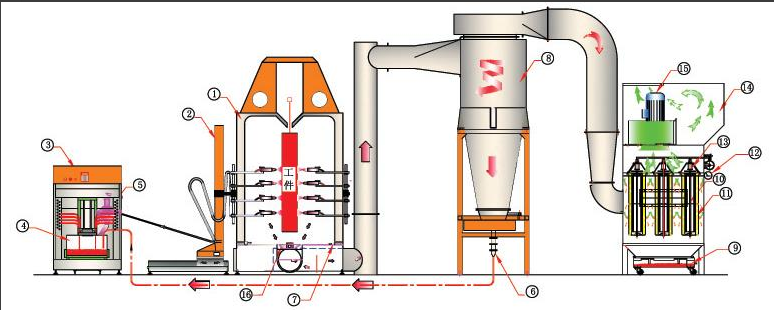

impushana ithuthwa ngephampu yempushana ngepayipi lempushana iye esibhamuni sokufutha. Impushana ishajwa endaweni ye-corona ye-electrode yesibhamu sesifutho futhi ikhangiswe ebusweni bomsebenzi ophansi. Ngemuva kwesihlungi somoya yenza isifutho sokucindezela okungekuhle kwangaphakathi, kanye nokuphela kwe-adsorption powder ngokugeleza komoya, ipayipi elingaphakathi elibushelelezi odongeni, ukuncela ukuhlukaniswa kwesishingishane esikhulu, izinhlayiya ziyimpushana esindayo, namandla omoya ajikelezayo e-centrifugal eduze kodonga lwesilinda sesivunguvungu, isisefo se-powder kuya ebhakedeni le-conical powder, futhi nge-extrusion valve recovery device. Impushana enezinhlayiya ezikhanyayo igeleza epayipini lesibili nomkhathi wokukhipha. Impushana ihlungwa ngokuphelele ngesihlungi. I-rotary wing pulse eyakhelwe ngaphakathi ishaya ngaphakathi nangaphandle kwesici sokuhlunga ukuze ishaye impushana iwele ebhakedeni lempushana, futhi izigcine ihlanzekile, igcine amandla okungena komoya asebenzayo.

| Izinhlobo zempushana | Ifanelekele ukumbozwa ngempushana ephilayo |

| Isivinini seketango lokumiswa | Ngokwezidingo zamakhasimende |

| Uhlobo lokudlulisela | I-Underslung Conveyer |

| Ukuzungezisa isiqeshana ngomzuzu | Anginayo |

| Izinga lokushisa le-workpiece | <35℃ |

| Izidingo zendawo yokusebenza | Umswakama ohlobene <75%, nezinga lokushisa elizungezile: <40℃ |

| Ukujiya okumaphakathi kokunamathela | Ngokwezidingo zamakhasimende |

| Ukuze zimbozwe workpieces | - |

| Impushana yokugaya kabusha | 10 izinhlobo |

| Inombolo yezinhlobo zemibala yempushana | 10 izinhlobo |

| "I-automatic slot (kuhlanganise ne-fixed slot) ohlangothini ngalunye" | Ezinhlanu |

| Isivinini sokugeleza komoya eduze | <0.1 m/s |

| "Encore LT Umsebenzi weManuwali Fafaza isibhamu kanye ngesilinganiso sempushana" | 70% (i-Aksu polyester thermosetting powder coating in test flat ebhodini) |

| Ithebula lokusebenza lezandla | 2 iziza zokufutha ezenziwa ngezandla |

| Izinga lokuphakelwa kwamandla | Isistimu yezintambo ezinhlanu zezigaba ezintathu, 380 V, 50 Hz, ububanzi bokushintshashintsha kwamandla kagesi okungu-+/-10% |

| "Umoya omncane ocindezelwe usetshenziselwa ukulinganisa" | 5.56 square metres / min * 2 |

| Umoya ocindezelwe ophezulu usetshenziselwa ukulinganisa | 6.03 m³ / iminithi * 2 |

| Ingcindezi yokufaka ephezulu | 8 amabha (8.0 Mpa) |

| Ingcindezi yokufaka encane | Amabha angu-6 (0.6 Mpa) |

| Umoya ocindezelwe uqukethe uwoyela, ubuningi bamanzi kanye nezinhlayiya | Iphoyinti lokucindezela kwamazolo -20℃ noma okuqukethwe kwamanzi 1.3g / m³, okuqukethwe kukawoyela 0.01 ppm, nothuli inani 0.01 μm |

| Imishini yokufafaza ngempushana imisiwe | "Sebenzisa 3-5 izimpande ububanzi 32 mm ithubhu lathayela, ubude mayelana 3000 mm, eshayelwa emhlabathini phansi emhlabeni" |

| Ukusetshenziswa kukagesi okuphezulu | 60.0 kW |

| Iphansi / umgodi | "A. Umthamo wokuthwala ubuso: amathani angu-5 / imitha yesikwele; B. Ukucaba kuyadingeka kuwo wonke ama-mm angu-1,000 ubude, amaphutha aphezulu naphansi ebangeni elingu-<1.5 mm." |

| Izinga lokuhlukaniswa kwesishingishane | 97% (ngaphansi kuka-3% kasayizi wezinhlayiyana zempushana ngaphansi kuka-10 um) |

| Umdwebo wesakhiwo sesisetshenziswa kanye neshadi lokugeleza kobuciko bomsebenzi | Bona imidwebo ukuze uthole imininingwane |

| Okunye | Anginayo |

| Igama lento | Imininingwane Yento | Imodeli | Incazelo | Ubuningi | Iyunithi |

| Futha uhlelo lokuthwala izibhamu | Ikheshi | I-YW2000 Digital Reciprocating Machine | (Okuphindaphindayo) Umshini ophakamisayo othwala umthwalo ongu-50kg; (I-Synchronous Belt) isakhiwo, ukusebenza okuphindaphindiwe, okuzinzile futhi okuhlala isikhathi eside | 2 | Setha |

| Ukushintsha umbala ngokushesha kanye nohlelo lwesikhungo sokuhlinzeka ngempushana | Ukushintsha umbala wesikhungo sempushana | Isikhungo Sokuhlinzeka Ngophuphu Okungenathuli | Ifakwe i-powder hopper engu-120kg, efakwe i-fluidizer egeleza kakhulu, ukuze inikeze impushana efanelekayo yesibhamu sokufutha, futhi ifake amaphampu okuphakela impushana ayi-12. | 1 | Ucezu |

| Isikrini sempushana | Umbhede Onoketshezi Ogelezayo Odlidlizayo | Umbhede ozimele odlidlizayo omanzi, ububanzi bungu-500mm, anezikhala eziyi-100. | 1 | Setha | |

| Futha igumbi lempushana | Ibhodi legumbi elipinki kanye nebhodi eseceleni | Amaphaneli Wall Wall Yepulasitiki Yepulasitiki | Amaphaneli odonga oluyimpushana nangaphezulu ashiselwe ngamapulasitiki obunjiniyela angu-6mm no-12mm angenisiwe, kanti ngaphansi ashiselwe amapulasitiki obunjiniyela angu-10mm, ahlala isikhathi eside. | 1 | Setha |

| Uhlelo lokubuyisela | Cyclone Components | Isihlukanisi Somoya Esikhulu Esiyinhloko | Uhlelo olukhulu lokubuyisela uthuli oluhlukanisa umoya lusebenzisa isimiso sokuhlukaniswa kwe-centrifugal. Impushana esedokodweni itholwa yiphampu yomoya kusihlukanisi somoya esikhulu, esihlukanisa ngokuzenzakalelayo impushana ye-ultrafine kungxube yempushana nomoya. Izinga lokuhlukaniswa kwesihlukanisi somoya esikhulu ngu-≥97%. | 1 | Setha |

| Isistimu yokuhlunga okuthunyelwe kwesibili | Isici sesihlungi se-Membrane | Isici sokuhlunga ulwelwesi lwe-Dongli sinokuklama okusha nokusebenza okuhle kakhulu, okungakhuphula indawo yokuhlunga ephumelelayo, kuthuthukise ikhono lokuzihlanza futhi kunciphise ukumelana nesistimu. Isici sokuhlunga sisetshenziswa njengengxenye eyinhloko yokutholwa kwempushana kanye nedivayisi yokuhlunga. | 24 | Setha | |

| Ifeni Yokonga Amandla Esebenza Kakhulu, I-South Ventilator, Ifeni YaseNingizimu | 30.0KVA motor kanye ne-South Ventilator fan blade (ivolumu yokudonsa umoya 20000Nm³/h). | 1 | Setha | ||

| Umzimba Wethangi Lokubuyisela Impushana Yesistimu Yesibili Yokuhlunga | Lo mzimba wethangi usetshenziselwa ukubuyisela impushana, kulula ukuyihlanza. Ngaphansi kunebhokisi lokuqoqa imfucuza egudlukayo, futhi ingxenye engaphezulu yethangi ine-杠杆 control main switch yokuvula nokuvalwa kwamandla amakhulu. | 1 | Setha | ||

| Uhlelo lukagesi | Uhlelo oluphakathi lokufafaza lwegumbi lempushana | I-Rack-Mounted Vertical PLC | Lawula ukuvulwa nokuvalwa kwamandla amakhulu, lawula ukuqala nokumiswa kwe-spray booth, lawula uhlelo lokuhlanza isibhamu se-spray, lawula umshini wokuphakamisa, njll. Yonke imisebenzi yemishini ingaqedwa ngesikrini sokuthinta. | 1 | Setha |

| Ukukhanyisa kwegumbi lempuphu | 600LU | Ukukhanyisa okungu-600LU, kungangeni uthuli, amaqembu ayi-6 edokodweni, amaqembu ama-2 ohlangothini lokuvula okwenziwa ngesandla. | 6 | Iqembu | |

| Iwaranti yezingxenye eziyinhloko | I-Booth Internal Standard Configuration | Lonke uhlelo lwedokodo luqinisekisiwe unyaka owodwa (ngaphandle kokugqoka izingxenye). | 1 | Iqoqo |

| Igama lento | Ibhrendi | Isikhundla |

| Isilawuli Sengqondo Ehlelekayo | I-Siemens (Germany) | I-S7-200 |

| I-Human-Machine Interface | I-Siemens (Germany) | I-KTP 600DP |

| I-Cam Switch | U-Moeller (Germany) | P3-100 |

| I-circuit breaker | I-Schneider (France) | I-C120H, OSMC32 |

| Isixhumi se-AC | I-Schneider (France) | LC-D, LC-E |

| Izinkinobho kanye Izibani Inkomba | I-Schneider (France) | ZB2, XB2 |

| I-Thermal Relay | I-Schneider (France) | LRD, LRE |

| Isifaki khodi sikagesi | U-Omron (Japan) | I-E6B2-CWZ6C |

| I-Fluidization Plate | I-Tokyo (Japan) | Ibhakede le-Fluidization |

| Ukushintsha Umkhawulo | I-NAIS (Japan) | I-AZ7311 |

| I-Proximity Switch | OGULAYO (Germany) | I-IME12-04NNSZW2S |

| I-Solenoid Valve | I-AIRTAC (Taiwan) | Spray Booth Cleaning Air Knife |

| I-Lifter Digital Inverter | I-Mitsubishi (Japan) | FR-D700 |

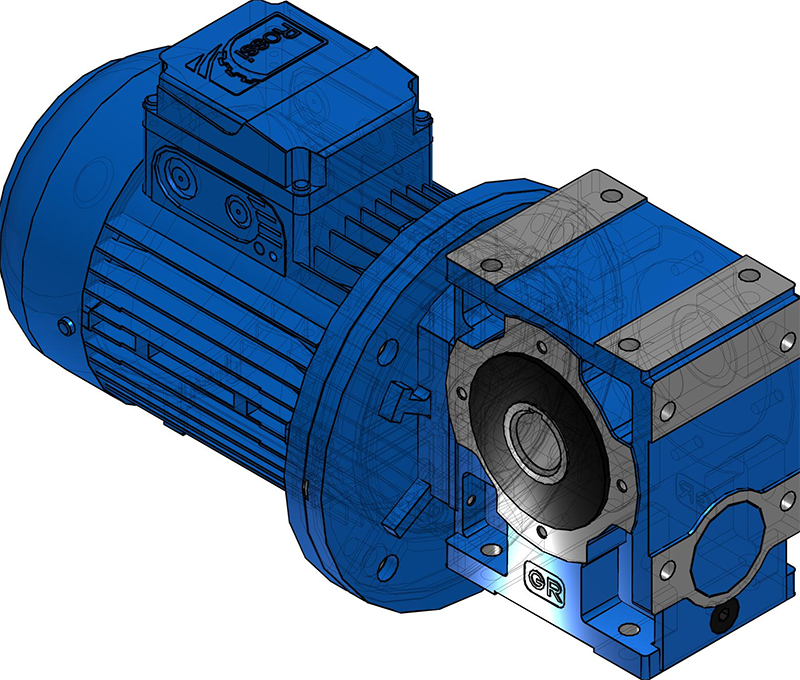

| Lifter Gearbox | I-TRANSTECNO (Italy) | Ukuphakamisa Ukuphakamisa |

| I-Lifter Motor | I-Siemens (Germany) | I-Siemens (Germany) |

| Isici Sesihlungi Se-Membrane ye-PTFE Nano-Coated | I-Toray (Japan) | Hlunga |

| I-Exhaust Fan | I-Nanfang Fan | Hlunga |

| Sandwich PP Engineering Plastic Plastic | I-New Helmer noma i-Klinger (Germany) | Spray Booth |

| Umbhede Owuketshezi Odlidlizayo | Tuzhong | 80 Mesh Screen Iyatholakala |

| Igama lento | Imininingwane Yento | Incazelo | Ubuningi | Iyunithi | Isithombe | |

| Uhlelo lokubuyisela | Uhlelo lwe-Cyclonic | Isihlukanisi Sesishingishane Esiyinhloko (Esikhulu Esikodwa). | Ububanzi: 1400mm Ubude: 5350mm Isihlukanisi esikhulu sesishingishane samukela umgomo wokuhlukaniswa kwe-centrifugal. Impushana etholwe yisihlungi imuncwa kusihlukanisi esikhulu sesishingishane, esihlukanisa ngokuzenzakalelayo impushana ye-ultrafine kungxube yempushana yomoya. | 1 | Setha | |

| Umgudu Womoya Wokuhlanza Ovulelekayo | Ukuze kuqinisekiswe ukushintshwa kombala, indawo engezansi yedokodo lokufutha, indawo yokungena komoya, kanye namapayipi axhumayo edokodo lokufutha aklanywe ngokunengqondo anezicabha okulula ukuzihlola nokuyihlanza, ukuze kube lula ukuhlanzwa kwansuku zonke nokuhlola kwangaphakathi. | 1 | Setha | |||

| Isistimu yokugaya kabusha | I-Toray Membrane Filter Cartridge (Japan) | Usebenzisa izinto zokumboza ulwelwesi olusezingeni eliphezulu (i-PTFE), impilo yesevisi ye-cartridge yokuhlunga ingafinyelela iminyaka engaphezu kwemi-5. Ingakwazi ukuhlunga i-ultrafine powder yama-microns angu-0.1-0.3. I-exhaust gas ikhishwa ngokuqondile endlini. I-cartridge yokuhlunga yenziwe ngobuchwepheshe obukhethekile, kulula ukuyihlanza, futhi inempilo ende yesevisi. | 24 | Izingcezu | ||

| Izingxenye Zokubuyisela Isihlungi Sangemuva | Le ngxenye inebhakede lokuqoqa imfucumfucu. Ikhatriji yesihlungi isebenzisa okokuhlunga okunameva ukuze kuhlukanise umoya, ukuze izinga lokutholwa kwempushana libe ngu-≥99.9%. I-cartridge yesihlungi ihlanzwa ngokushintshwa komoya okucindezelwe futhi itholwa ngohlelo lokudlulisa ukucindezela kokuhlunga okuhlukile. | 1 | Setha | |||

| IFani Eyonga Amandla Esebenza Kakhulu kanye ne-South Ventilator Impeller | Iyingxenye eyinhloko yedivayisi yokutholwa kwesihlungi sesibili. Amandla enjini angu-30KW, futhi umthamo womoya ungu-20000Nm³/h; ngedivayisi yokunciphisa umsindo ophezulu. | 1 | Setha | |||

| Izici: Ayikho i-backflow noma i-siphon phenomenon; Idivayisi yokuphakamisa umoya; Ukwakhiwa kwebhakede le-cone ukuze kube lula ukuqoqwa kwempushana; Ukuxhuma okusheshayo ukudluliswa kwe-powder esibonakalayo esizinikele; Kuhlanganiswe ne-automatic powder return blowback, isilinda esisodwa kulula ukusihlanza; Uhlelo lwamapayipi olulula futhi oluvalekile; I-air duct yokubuya inikeza ukuqina okungcono, isisekelo esihle, futhi ithuthukise ukuphepha kwenqubo yokuhlanza; Faka umnyango wokuhlanza endaweni yokuxhuma ekamelweni lokufafaza impushana, futhi opharetha angavula ngokuqondile umnyango ukuze ahlanze ingaphakathi lapho eshintsha imibala. Ukuqaliswa okulula nokusheshayo kokushintsha kusuka kumnyama kuya kumbala okhanyayo ukuthi' inqobo nje uma kuyabonakala, kungahlanzwa kahle '. | ||||||

| Igama lento | Umsebenzi | Incazelo | Ubuningi | Iyunithi | Isithombe | |

| Ukushintsha umbala okusheshayo kanye nohlelo lwesikhungo sokuhlinzeka ngempushana | Isikhungo Sokuhlinzeka Ngempushana | Isikhungo Sokubuyisela Impushana | Ixhunywe uhlelo olukhulu lokutakula isishingishane; ukusebenza kwesikhungo esishintsha ngokushesha, nomsebenzi wemodi esheshayo nemodi enensayo, kuhlanganisa ukuguquguquka nokulula kokusebenza; icubungula impushana isuka kumpushana yasekuqaleni noma idivayisi entsha eyimpushana, idivayisi edidiyelwe yokuguquguquka okuzenzakalelayo. Ihlanganisa ukulawulwa kukagesi, iqaphe indawo ngomtshina wezinga, umtshina wezinga ulawula ukukhuphuka nokuwa kwensiza yokuphakela impushana, futhi idivayisi yokuphakela impushana ifakwe impompo egcwele yokubuya yangaphakathi kanye negesi ewuketshezi. Ipayipi lokumunca, iphampu eyimpuphu, ipayipi nesibhamu sokufutha zingahlanzwa ngokuzenzakalelayo. Impushana etholiwe ithunyelwa ngqo ethangini lokuphakela impushana, kanye nesishingishane esikhulu esididiyelwe umshini wokuhlanza okuzenzakalelayo. | 1 | Setha | |

| I-Powder Barel | Plastic Square Barrel | Umphongolo wepulasitiki oyisikwele we-powder fluidized ufakwe i-fluidizer egeleza kakhulu, engakwazi ukukhipha kangcono i-powder emgqonyeni wempushana futhi idlulisele impushana efanelekayo kusibhamu sesifutho. | 2 | Izingcezu | ||

| Izici Zokuklama | Imvamisa ithathwa njengengxenye ewumgogodla wokukhiqiza okuzenzakalelayo; Isisefo esihlanganisiwe sempushana sikagesi esikhiphekayo (250 μ m usayizi wembotshana); Isikhungo sokuhlinzeka ngempushana siklanyelwe ngokukhethekile ukushintsha umbala ngokushesha, esikhundleni sebhakede lempushana elivamile. Isikhungo sokuhlinzeka ngempushana siyingxenye ehlanganisiwe ohlelweni lokushintsha umbala ngokushesha, oluthinta izinga lokufafaza lomkhiqizo wokugcina. Beka ibhokisi lempushana elihlinzekwe umphakeli wempushana endaweni yebhakede lempushana emanzi, futhi ngemva kokusetshenziswa, buyisela ibhokisi lempushana endaweni yokugcina impahla; | |||||

| Isimiso Sokuklama | Indlela yokusebenza evamile yesikhungo sokuphakela ngempushana ukubeka ibhokisi lempushana etafuleni lokudlidliza. Ngokweziqondiso zomtshina wezinga lempushana, wonke amashubhu okumunca iphampu yempushana afakwa kumpushana, futhi ishubhu ye-fluidization isetshenziselwa ukugcwalisa impushana ezungezile. Impushana ewuketshezi iphonswa epayipini eliyimpuphu ngephampu yempushana bese ifuthwa ngesibhamu sokufutha. Impushana engakafuthwa endaweni yokusebenza iwela phansi egunjini lokufafaza bese imuncwa kusihlukanisi sesishingishane, ibe ingxube yomoya kanye nempushana. Ku-separator yesivunguvungu, impushana iyahlukaniswa futhi ibuyiselwe esikhungweni sokuhlinzeka ngempushana nge-valve yesigaba esiminyene. Ukuze ugweme ukungcola, impushana ebuyiselwe esikhungweni sokuhlinzeka ngempushana ihlungwa ngesisefo sempushana ngaphambi kokuba ingene ebhokisini lokuhlinzeka ngempushana. Lapho ushintsha imibala, wonke amaphampu empushana ayaphakanyiswa ebhokisini lempushana bese ibhokisi lempushana likhishwa etafuleni lokudlidliza. Inqubo yokuhlanza iqala, futhi wonke amaphampu empuphu kanye namapayipi okumunca ehliselwa endaweni yokuhlanza, okuyi-valve eshayayo yesikhulumi sokudlidliza. Impushana esodongeni lwangaphakathi lomgwaqo oyimpuphu ihlanzwa ngokuzenzakalelayo ngomoya ocindezelwe. Ngalesi nqubo yokuhlanza, izindonga zangaphakathi zepayipi lokumunca impushana, iphampu yempushana, ipayipi lokuphakela ngempushana, kanye nesibhamu sokufutha konke kuyahlanzwa. Ingaphandle lephampu eliyimpuphu lingahlanzwa ngesibhamu esishaywa ngesandla. Vala ibhokisi lempushana, ulibuyisele endaweni yokugcina izimpahla, bese ufaka elinye ibhokisi lempushana elinombala. Impushana esele ohlelweni igaywa kabusha ingene ku-waste powder hopper. Ipayipi lokubuyisela elisuka kusihlukanisi sesishingishane ukuya esikhungweni sokuphakela ngempushana nalo liyahlanzwa ngomoya ocindezelweyo. Ngemuva kokuthi inqubo yokuhlanza isiqediwe, ungaqala ukufafaza omunye umbala. Kunconywa ukuthi uthumele impushana egaywe kabusha ku-waste powder hopper phakathi nemizuzu embalwa yokuqala yokukhiqizwa kombala olandelayo, futhi ungayisebenzisi. | |||||

| Igama lento | Imininingwane Yento | Incazelo | Ubuningi | Iyunithi | |

| Uhlelo lokulawula ugesi | Uhlelo oluphakathi lokulawula lwegumbi lokufafaza ngempushana | I-Rack-Mounted Vertical Vertical PLC Isistimu Yokulawula Emaphakathi Yokuhlinzeka Ngempuphu Yebhuthi Ye-spray | Isistimu yokulawula ye-Siemens rack-mounted centralized, isixhumi esibonakalayo esinobungane somshini womuntu, sisebenzisa izimpawu ezicacile, kulula ukusebenza. Isixhumi esibonakalayo singabonisa isimo sokusebenza sesistimu njengesiphephetha-moya nesibhamu sokufutha, esinemisebenzi eminingi efana nokusetha ipharamitha, isibonisi solwazi lwe-alamu, ukwaziswa kokulungisa, nokuvikelwa komnyango wekhabethe. Inemisebenzi efana nokuqina kokulawula, ukumisa okuphoqelekile kwesiphakamisayo, isilawuli se-logic esihlelekayo, i-alamu yokubona ilangabi, ukulawula ukuqala nokuma kwedokodo lokufafaza, ukulawula ukuvulwa nokuvalwa kokuphakelwa kwamandla okuyinhloko, ukusebenza kahle kokunqanda ukuphazamiseka, kanye nokuhambisana nezindinganiso zezimboni zase-Europe ze-CE. | 1 | Setha |

| Umsebenzi: Zonke izingxenye ziyizinto zikagesi zegama lomkhiqizo, ezinobufakazi obuthathu, futhi zonke iziqephu zesifunda ziyi-Siemens. Ikhwalithi izinzile. Izinto zikagesi nolayini zithobelana nezinhlinzeko "Zezisetshenziswa zikagesi Ezindaweni Zokufutha" kanye "Nezisetshenziswa zikagesi Ezindaweni Eziqhumayo Nezokufaka Uthuli" ku-GB15607-2008 4.8.1, futhi izintambo zikagesi ezingena endaweni yokufutha zithobelana nezinhlinzeko ze-GB50058. | |||||

| Igama lento | Incazelo | Ubuningi | Iyunithi | |||

| Isistimu yedivayisi yokuvikela ukuqhuma kwegumbi lempuphu | I-A716/IR3 Iphuzu Lomtshina Womlilo | Lo mkhiqizo uthuthukiselwe ku-32-bit processor, ehlanganiswe nama-algorithms amaningi athuthukiswe ngokukhethekile ukutholwa komlilo. Ngenkathi ithuthukisa kakhulu isivinini sokuphendula, futhi inokuvikeleka okuphezulu kuma-alamu amanga. Ingasetshenziswa ezinhlelweni ezingaphakathi nangaphandle ngenani elikhulu lemithombo ye-alamu engamanga. | 1 | Setha | ||

| I-Big Whirlwind Explosion proof System | I-Post-Filter Flameproof Valve | Ifakwe phakathi kwe-air inlet enkulu nesihlungi, amamitha angu-3 ukusuka kuhlaka lokuhlunga. Lapho ukucindezela okuphambene kwe-valve ye-flameproof kukhulu kunokucindezela okubekiwe, i-valve ye-flameproof iyavala. Ubuchwepheshe obungashisi ilangabi bungavimbela ukuqhuma ukuthi kungasakazeki emishinini engaphambili, kugweme ukuqhuma "kwesibili" noma ukushisa. Isimiso siwukusebenzisa ukucindezela okukhiqizwa ngesikhathi sokuqhuma ukusunduza i-valve ehambayo ukuvimba ilangabi lokuqhuma nokucindezela. Indawo yokufaka iphakathi kwesendlalelo esimaphakathi nesendlalelo esingezansi sozimele wesihlungi. | 1 | Setha | ||

| Isistimu yokuhlunga ubufakazi bokuqhuma | Idivayisi Ye-alamu Yokuthola Ukucindezela Okuhlukile | Kufakwe phakathi kwesendlalelo esingaphezulu nesendlalelo esingezansi sozimele wesihlungi. Uma ingcindezi idlula ibanga elimisiwe, isistimu yokulawula ikhipha i-alamu, ikhuthaza ukuthi kushintshwe into yokuhlunga, i-vane ejikelezayo, nedivayisi yevalvu yokubuyisela umoya. | 1 | Setha | ||

| I-Flameless Venting Device (Idivayisi Yokufaka I-Flameproof) | Idivayisi yokungenisa umoya engenalangabi iqukethe iphaneli elingashi, idiski ephukile, ulayini wokuxhumana ongashi, nesixhumi. I-disc yokuqhuma ifakwe idivayisi yesignali, engaxhunywa kukhabhinethi yokulawula noma i-alamu ngomugqa woxhumano ongashi, futhi ixhunywe nefeni noma ezinye izinto zokusebenza. Umkhiqizo: I-Huili, ihlinzeka ngemibiko yokuhlolwa kokutholwa nesitifiketi. | 1 | Setha | |||

| I-Pneumatic Powder Return Valve | Ivalvu yokubuyisela impushana yomoya iqoqa umlotha emlotheni 斗 bese iwuthululela epayipini lokubuyisela umfutho omuhle. Umjikelezo wokusebenza we-valve ye-pneumatic unqunywa ngokuya kwesikhathi. Isikhawu phakathi kwevalve yomoya kanye nomlotha 斗, umfutho womoya womlotha 斗 kanye nevalvu yomoya, kanye nomfutho womoya wevalvu yomoya kanye nepayipi elidluliselayo kugcinwa ngokulingana. | 2 | Amasethi | |||

-

Umshini Wokuhlanganisa we-Automatic Side Plate Assembly ...

-

I-Modular Air Cooled Scroll Chiller

-

Umshini Wokushaja Oyisiqandisi Othuthukile Wokusebenza...

-

Idokodo lokufutha elenziwe ngokwezifiso elinamaphaneli angashi ...

-

I-Intelligent Leak Detector Yesiqandisi Esiqondile...

-

I-Intermediate Frequency Induction Heating Sealin...